Wave soldering machines are mainly used for THT (Through-Hole Technology), components that (manually or fully automatically) are inserted through the printed circuit board at the top and soldered at the bottom by means of soldering in a liquid solder wave (solder pot).

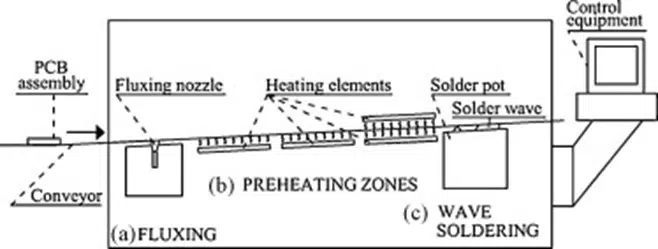

Schematic of a wave soldering machine:

Step 1 Flux application:

The first step in this machine is flux application. This is usually done by a spray fluxer. The spray nozzle moves back and forth and sprays the flux against the underside of the assembled circuit board.

Step 2 Preheating:

Then the assembled circuit board is heated to activate the flux.

Step 3 Wave soldering:

When the flux activation temperature is reached, the assembled circuit board passes through the solder wave and the solder flows up through the plated holes to the top side of the circuit board.

Step 4 Cooling:

Finally, the soldered assembled circuit board is cooled and cleaned. The assembly is now ready for inspection and functional test.

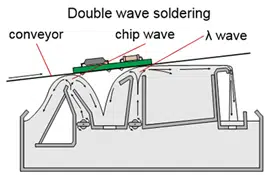

The SMD components (surface mounted devices where the leads are not inserted through the printed circuit board) can also be soldered with a wave soldering machine provided they are located on the bottom side of the printed circuit board. These small components are glued and go through the liquid solder wave. For the smallest SMD components, the wave soldering machine has a separate (rough) wave, the so-called CHIP wave:

However, nowadays more and more SMD components are used and the Reflowoven is the better solution for this.