CNC (Computer Numerical Control) machining is a subtractive manufacturing technology: parts are created by removing material from a solid block (called the blank or the workpiece) using a variety of cutting tools.

This is a fundamentally different way of manufacturing compared to additive (3D printing) or formative (Injection Molding) technologies. The material removal mechanisms have significant implications on the benefits, limitations and design restrictions of CNC. More on this below.

CNC machining is a digital manufacturing technology: it produces high-accuracy parts with excellent physical properties directly from a CAD file. Due to the high level of automation, CNC is price-competitive for both one-off custom parts and medium-volume productions.

Almost every material can be CNC machined. The most common examples include metals (aluminum and steel alloys, brass etc) and plastics (ABS, Delrin, Nylon etc). Foam, composites and wood can also be machined.

The basic CNC process can be broken down into 3 steps. The engineer first designs the CAD model of the part. The machinist then turns the CAD file into a CNC program (G-code) and sets up the machine. Finally, the CNC system executes all machining operations with little supervision, removing material and creating the part.

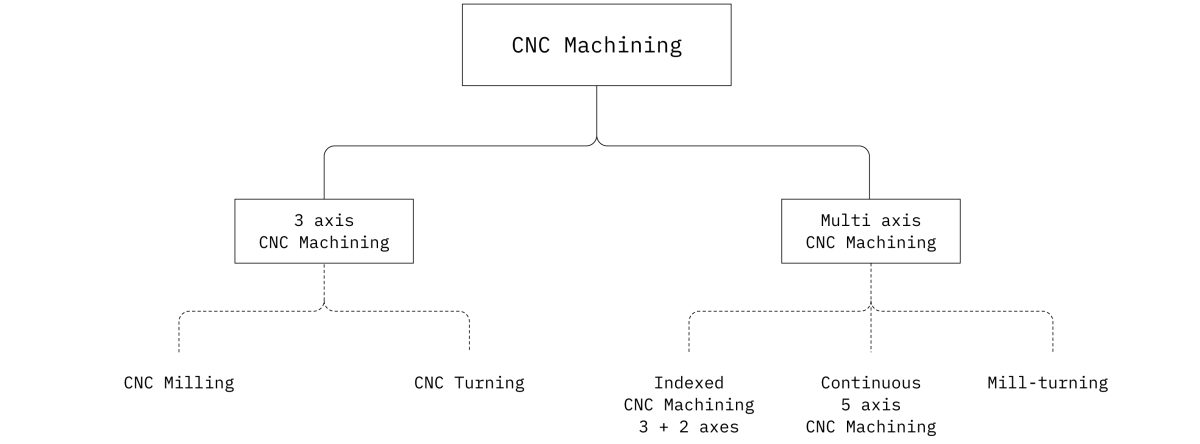

Types of CNC machines

In this guide, we will focus on CNC machines that remove material using cutting tools. These are the most common and have the widest range of applications. Other CNC machines include laser cutters, plasma cutters and EDM machines.

- 3-axis CNC milling machines manufacture parts with relatively simple geometries with excellent accuracy and at a low cost.

- CNC lathes have the lowest cost per unit, but are only suitable for part geometries with rotational symmetry.

- Indexed 5-axis CNC milling machines manufacture parts with features that do not align with one of the main axes quickly and with very high accuracy.

- Continuous 5-axis CNC milling machines manufacture parts with highly complex, 'organic' geometries and smooth contours, but at a high cost.

- Mill-turning CNC centers combine the benefits of CNC turning and CNC milling into a single system to manufacture complex parts at a lower cost than other 5-axis CNC systems.