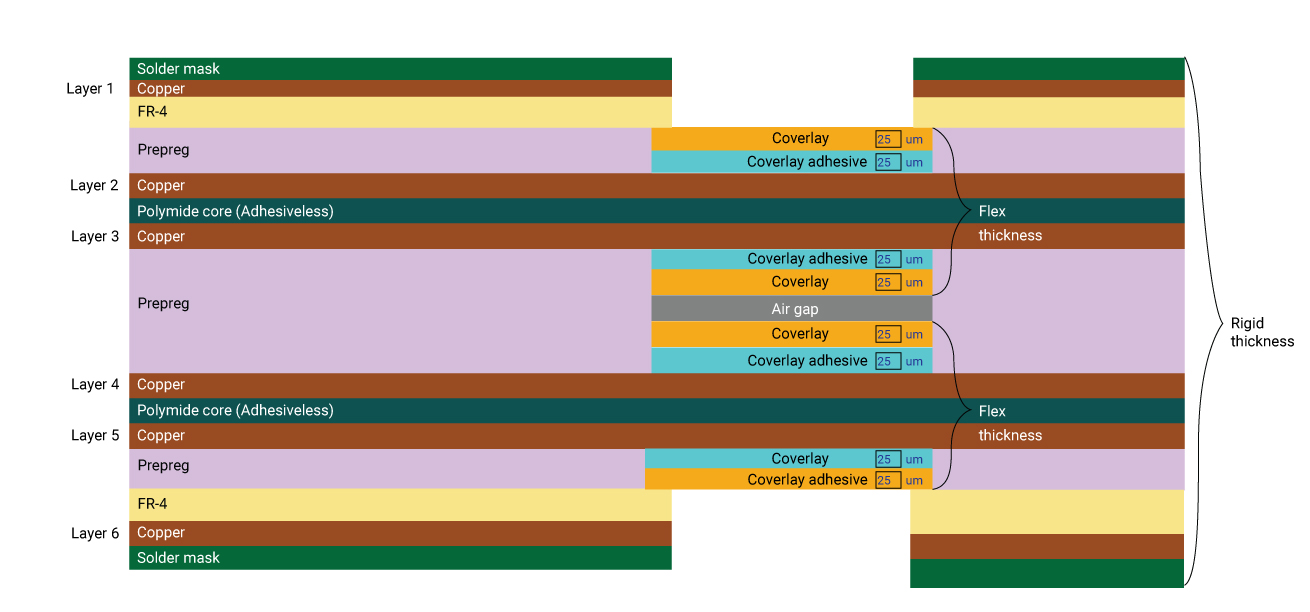

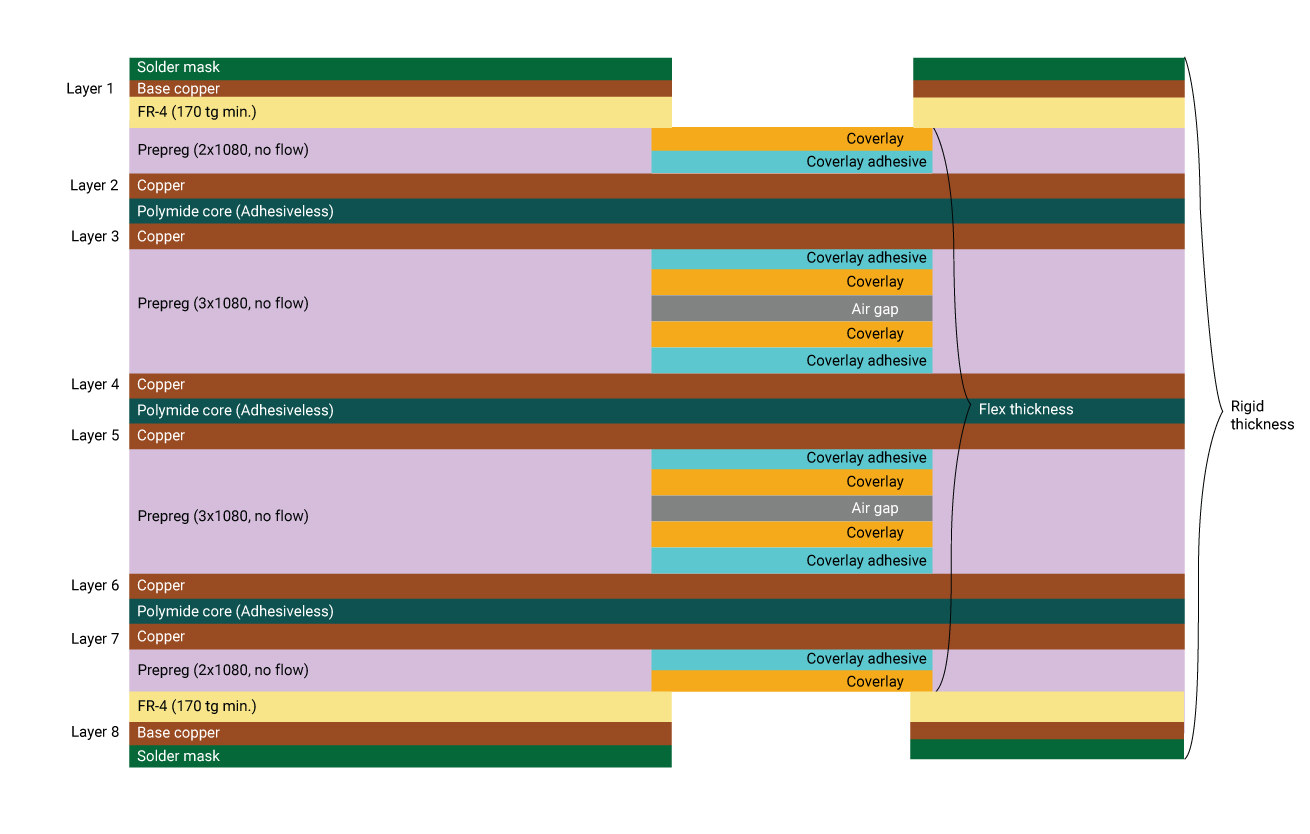

To address the reliability issues of rigid-flex PCB, IPC has developed a construction method known as air gap construction.

In air gap construction, the flex layers are kept as several independent sets of no more than three layers per set. Although 2 layers per set are optimum, the IPC 2223 standard allows for 3 layers, if a design incorporates controlled impedance lines in the flex area. Here, one layer can be configured as a stripline, with two adjacent layers acting as shields. As seen in the above PCB stack-ups, the air gap construction eliminates the flex adhesives within the rigid sections. This also addresses the via hole reliability issues.