BGA is the abbreviation of Ball Grid Array. This, in a general form, is an array of small sized / tiny metallic conductor balls that are arranged in a harmonies form on the Board that we proceed towards making a PCB.

A Ball Grid Array Integrated Circuit is a surface mount device (SMD) component that possesses no leads. This SMD package employs an array of metal spheres that are made of solder called the solder balls for connections to the PCB (Printed Circuit Board). These solder balls are affixed to a laminated substrate at the bottom of the package.

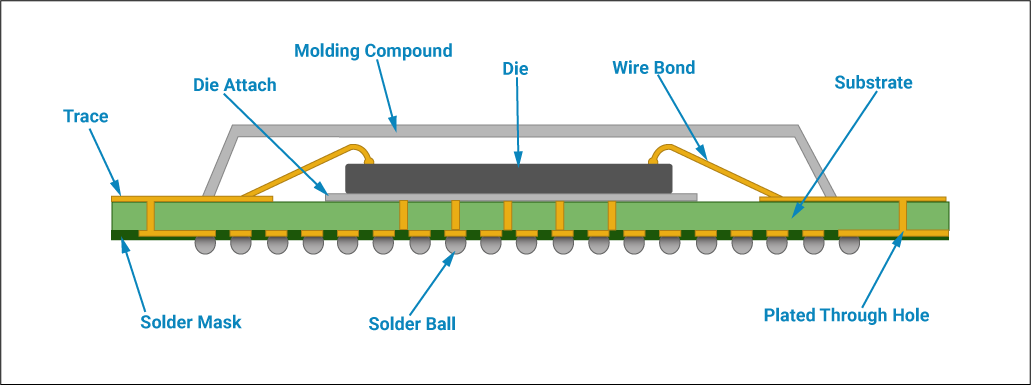

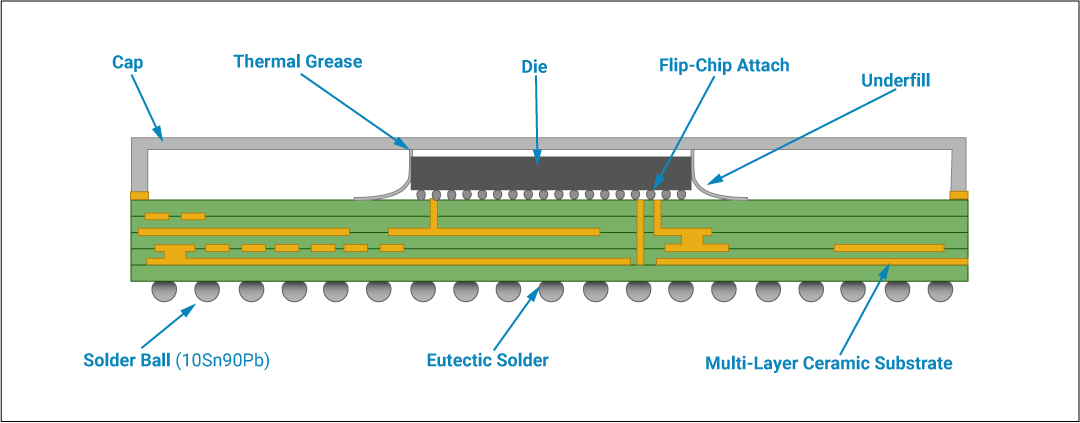

Figure (1) and Figure (2) display two examples of how BGA devices are constructed. Figure (1) shows how the BGA die/chip is mounted on the substrate and connected to the substrate by wire bonding technology. Figure (2) displays how the BGA die is connected to the substrate using flip-chip technology.

The BGA die connections are routed to the solder balls using metal traces on the substrate. BGA packages can provide more IO connections compared to dual in-line or flat packages.

The connections from the die to the balls in BGA ICs are on average shorter than perimeter-only type connections such as DIP ICs. Thus, leading to better performance at high speeds.

BGA package types

In order to meet the variety of requirements for different types of assembly and equipment, a number of BGA variants have been developed.

- MAPBGA - Moulded Array Process Ball Grid Array: This BGA package is aimed at low-performance to mid-performance devices that require packaging with low inductance, ease of surface mounting. It provides a low cost option with a small footprint and high level of reliability.

- PBGA - Plastic Ball Grid Array: This BGA package is intended for mid- to high-performance devices that require low inductance, ease of surface mounting, relatively low cost, while also retaining high levels of reliability. It has some additional copper layers in the substrate that enable increased power dissipation levels to be handled.

- TEPBGA - Thermally Enhanced Plastic Ball Grid Array: This package provides for much higher heat dissipation levels. It uses thick copper planes in the substrate to draw heat from the die to the customer board.

- TBGA - Tape Ball Grid Array: This BGA package is a mid- to high-end solution for applications needing high thermal performance without an external heatsink.

- PoP - Package on Package: This package may be used in applications where space is at a real premium. It allows for stacking a memory package on top of a base device.

- MicroBGA: As the name indicates this type of BGA package is smaller than the standard BGA package. There are three pitches that are prevalent in the industry: 0.65, 0.75 and 0.8mm.