IC programming is the process of transferring a computer program into an integrated computer circuit. Older types of IC include PROMs and EPROMs

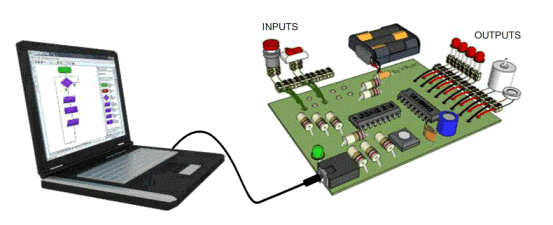

I believe you have already known that the answer is “programming”, someone also called “burning”.Programming, the process of transferring the program into the chip’s internal storage space.There are offline programming and online programming.