In the world of industrial electronics, the heart of many systems lies in printed circuit boards (PCBs). These small but mighty components are responsible for ensuring everything runs like clockwork. Yet, like any technology, they can encounter their fair share of challenges. Understanding the common problems and best repair approaches can help keep your PCB-powered systems humming smoothly.

Common problems impacting PCBs

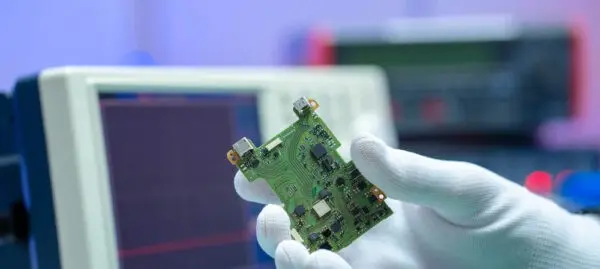

PCBs are delicate. Recognizing the types of defects that can arise over time and taking the necessary steps to identify them can help guarantee your components perform optimally. Here are some common problems to watch for:

- Component failures: Just as all things in life have a lifespan, so do PCB components. The wear and tear from factors like heat, vibration, and moisture can lead to components wearing out and failing. When one gives out, it can bring equipment to a grinding halt.

- Solder joint woes: Solder joints are the lifelines connecting PCB components. If a solder joint is cracked, poorly made, or broken, it can disrupt the flow of power, causing a domino effect of failures.

- PCB damage: The manufacturing environment can be harsh on PCBs. Be it from a collision, excessive heat, moisture, or chemicals, these factors can result in cracks, breaks, and corrosion. This damage can trigger component failures or short circuits.

PCB repair techniques

Knowing the problems is only half the battle. Equally important is understanding how to address these issues. Here are some common repair techniques to approach PCB complications and restore equipment to full functionality:

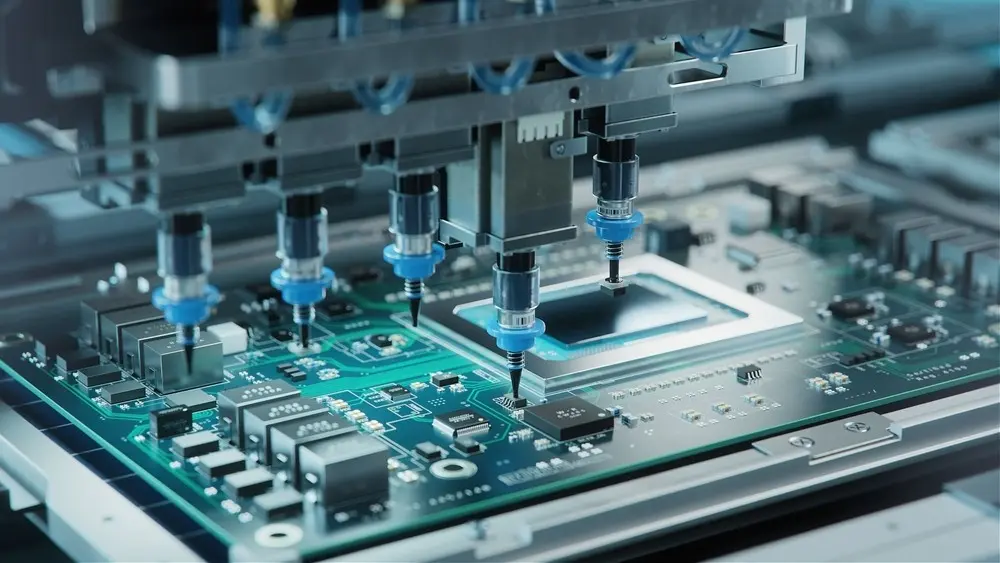

- Component replacement: When a component quits, swapping it for a fresh one is often the solution. A replacement can breathe new life into the PCB and restore functionality.

- Solder joint repair: If a solder joint is showing signs of wear and tear, it can usually be fixed through a process known as reflowing. This process involves re-melting the solder to mend the connection.

- PCB restoration: When damage strikes, the PCB might need some TLC. Restoration may include replacing damaged components or patching any cracks or breaks.

- Design refinement: Sometimes, it’s not the components causing the problems but the design. A flawed design, such as inadequate thermal management or poor component placement, can lead to failures. In such cases, redesigning and remanufacturing the PCB may be necessary.

How to avoid PCB problems

The saying “prevention is better than cure” holds true for PCB woes. Avoiding issues is the gold standard. It starts with meticulous design and manufacturing practices, including:

- Quality components: The foundation of a reliable PCB lies in its components. Using high-quality parts can significantly decrease the chances of component failure.

- Solid design practices: A well-planned design can be the difference between a resilient PCB and a troublesome one. Proper thermal design, component placement, and material selection are crucial.

- Thorough inspections: Inspections and quality assurance can catch potential issues before they evolve into full-blown problems.

When problems do arise, having a qualified repair technician at your side can be a game-changer. After all, in the intricate world of industrial electronics, every component matters.