This process is called "eviction" of a single board. It is often called "step-by-step repetition". Other terms used to describe arrays are: paneled, stepped, palletized, and collapsed and retained.

Why would anyone want an array?

The reason manufacturers want their board alignment is to help them through the manufacturing process. It allows them to load parts faster because they can load the entire array at once instead of one board at a time.Boards are loaded using automated equipment called "pick and place" machines . The device simply picks up parts (usually surface mount devices) and places them on the board.

Arranging boards often increases the cost of a single board. This happens because you get fewer boards on a production panel when they are in an array, rather than when running as individual boards. Although the cost of the single board will go up, the cost of the assembled board is lower due to the array configuration.

General Guidelines

Every electronics assembler and manufacturer has their own specific guidelines on how they want to set up the array for fabrication. These guides provide some fairly common ideas for general practices.

the size of the array

Array sizes range from 8 x 10 inches to 10 x 12 inches as the overall maximum size. If the PCB manufacturer were to use a production panel size of 18x24 and the available space of 16x22, the best fit for the largest array would be 7.8 x 10.8 inches. This will allow at least four arrays on the panel. If the array size is larger than this value, you will only be able to add two more arrays and the cost per board will increase significantly. Smaller array sizes can be used for smaller individual boards and still have good yields per panel.

guide

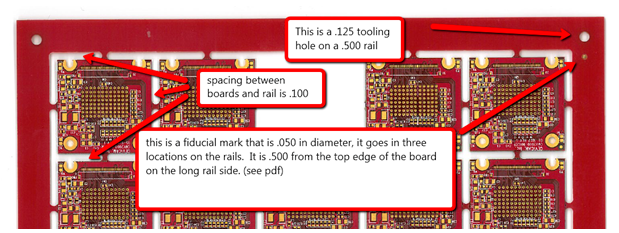

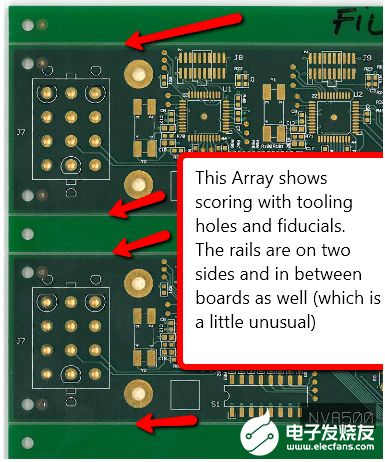

Rails are extra PCB material added to the sides of the array for easier handling during assembly. Rails can be located on all four sides of the array, or only on both sides. If you only have it on two sides, you can usually put a few extra on the panel, which will help keep the cost per board down.

datum point

Typically, three fiducials are required on the array and placed on the rails. The ideal size is 0.050 inches. The benchmark is a copper pad circle with the same finish as the rest of the board. This provides alignment targets for automated assembly equipment to keep things aligned. Some manufacturers may also require benchmarks on each individual board. However, in most cases there are pads or other features on a single board that can be used to provide additional alignment targets.

Tool hole

Tool holes in the four corners of the array (in the rails) are also common. Again, these are used to help with alignment and orientation when assembling the board. Typical size is 0.125 inches and they are non- plated .

array spacing

The spacing will depend on whether the array is scored or routed. For tab routing, the spacing is 0.100 in most cases. By scoring the boards and placing them next to each other, no spacing is required. There are two options for the "split board" we just mentioned - that is, how to separate the board after assembly. Options are scoring or tab rout.

scoring

Scoring means making a small "V" groove along the length of the board where they will separate. The grooves are usually 1/3 on the top and 1/3 on the bottom, leaving 1/3 of the material in place to hold the boards together.

When scoring, no part should be placed within 0.250" of the edge of the board. If they are closer than this, the parts may come loose during the de-boarding process. If the board is thicker than 0.062 inches and the scribe line is very long, it may take a lot of force to separate the board.

Label routing

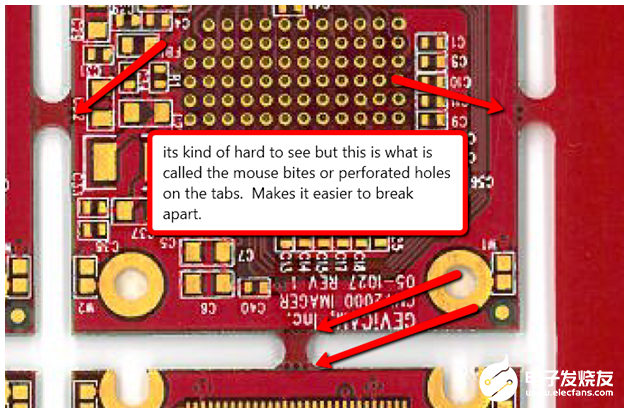

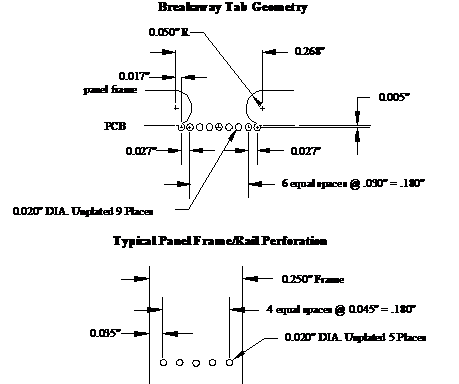

Tab rout arrays will leave a small tab on all four sides of boards that are attached to other boards or rails. This type of array is not as rigid as a scored array, but is easier to separate.

Labels are usually one on each side of each board and are usually 0.050 inches wide. They will usually drill small holes in the edge of the label on the outside line of the board. These small holes are called "rat bites" or "piercings." I've even heard of them being called "rat bites". Either way, they make it easier to snap the tabs off the board. They do leave rough edges, so some additional sanding or grinding may be required to smooth them out.

X is out

An X output means that one of the individual plates on the array failed the test and is marked with a marker . Some manufacturers allow a certain percentage of X output in the order, while others may require no X output on any array. Since there is no X output, this will make the board a bit more expensive, as the PCB manufacturer may need to manufacture a higher number of arrays to meet their volume order requirements.

How do you calculate the size of the array?

Many people use the Kwickfit program to calculate arrays, which is a very handy tool. If you have Kwickfit, here are the steps to get the best fit array:

Panel size set to 18 x 24 with 1 inch margins

Choose best fit array

Enter individual board dimensions

Maximum size 7.8 x 10.8

The minimum quantity is 1, the maximum quantity is 100

Click Calculate.

If you don't have kwickfit, you can also do this manually. Of course, a spreadsheet or calculator makes this easier.

Let's say the largest X dimension is 7.8 and the largest Y dimension is 10.8. Use the smallest size of a single board as the X dimension.

1. The first step is to determine your rail size

Rail size = _______

If your rail size is 0.5, you double it (rails on both sides) and subtract that size from the total available size of the X dimension.

Then subtract 1 inch from 7.8” = 6.8” inches. This is the "available" space for your array in the x dimension now.

2. The second step is to add your spacing to the dimensions of the board.

X dimension = _______

Spacing = __________

For example, your board is 1" with a 0.1 pitch. Add them all together and you have 1.1 inches.

3. The third step is to determine how much fits.

Divide 6.8 by your individual board size and add spacing. In this case, 6.8 divided by 1.1 = 6.1 So you will be able to install 6 1" size boards in the x dimension using 0.1 spacing and 0.5 rails.

4. Step 4 Add them together

NOTE: Since there is space on both sides of the board, you must add 0.1 to the total number of boards to get the correct overall size.

So here is the total number of X dimensions.

6 pcs * 1.1 = 6.6 + .1 (for extra space) = 6.7 + 1 (for rails) = 7.7” in X dimension then do the same process for Y dimension 10.8 – 1 = 9.8” free space 9.8 / 1.1 = 8.9 (must be rounded down) so equals 8 in the Y dimension 8 * 1.1 = 8.8 + .1 = 8.9 + 1 (for the rails) = 9.9" in the Y dimension. So you get 6 x 8 ( 48), overall dimensions are 7.7 x 9.9 with 0.500" rails and 0.100" spacing.

Now you can do this manually as I show here. Alternatively, you can visit our website and try our array calculator. It will do all the math for you and make a nice graphical image for you.

Edit : Lisa Wang