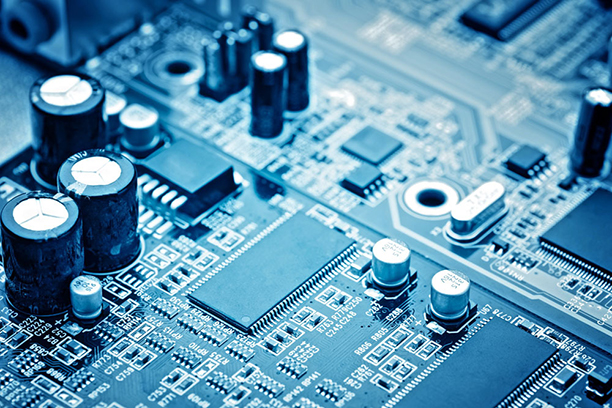

pcb via size guidelines for vias in pcb design is an important topic that is often mentioned. In high speed board design, multi-layer PCBs are often required. In other words, vias in high speed board design are also an important factor. You can think of this article as high speed pcb design guidelines, and we will talk about high speed pcb design rules. Usually, the pcb via hole comprises three parts: the hole, the pad area around the hole, and the POWER layer isolation area. Next, let us learn about circuit board via in high speed pcb design rules.

Types of vias in pcb design: pcb via size guidelines

what are pcb vias? The different layers of pcb are connected through the PCB VIAS. This hole is conductive through the electroplating layer. Types of vias in pcb design are generally divided into through pcb vias, blind pcb vias, and buried pcb vias. In the high speed pcb layout, pcb via hole also includes these three types.

Blind vias: One of the types of vias in pcb design is blind vias. It is located on the top and bottom surfaces of the printed circuit board with a certain depth and is used to connect the surface circuit and the inner circuit below. The depth of the hole and the diameter of the hole usually do not exceed a certain ratio.

Buried vias: Another one of the types of vias in pcb design is buried vias. Refers to the connection hole located in the inner layer of the printed circuit board, which does not extend to the surface of the circuit board.

Through vias: The last one of the types of vias in pcb design is through vias. This kind of hole passes through the entire circuit board and can be used for internal interconnection or as a component installation positioning hole. Because the through-hole is easier to realize in the process, the cost is lower, so the general printed circuit board is used.

These three types of Vias in pcb design have their functions and are indispensable. We must follow the high speed pcb design rules.

The impact of vias in pcb design

Vias in pcb design plays an important role in connection. For example, in high-speed PCB multi-layer boards, the signal transmission from one layer of interconnection line to another layer of interconnection line needs to be connected through hole vias. When the frequency is lower than 1 GHz, pcb via hole can play a good role in the connection. We can ignore the parasitic capacitance and inductance of circuit board vias in pcb design. When the frequency is higher than 1 GHz, The influence of parasitics in circuit board vias in pcb design on signal integrity cannot be ignored. At this time, the through hole vias appear as a discontinuous impedance breakpoint on the transmission path, which will cause signal reflection, delay, and attenuation. And other signal integrity issues.

When transmitting a signal to another layer through hole vias, reference layer of the signal line also serves as the return path of the via hole signal. The return current will flow between the reference layers through capacitive coupling and cause problems such as ground bounce.

High speed pcb design guidelines

The high speed pcb design guidelines comply with the rules in vias in pcb design. In high speed board design, a seemingly simple circuit board via often brings great negative effects to circuit design. In order to reduce the adverse effects of parasitic effects of vias in pcb design, the following points should be done in high speed board design:

(1) Choose a reasonable through hole vias size. For multi-layer general-density PCBs, it is better to use 0.25mm/0.51mm/0.91mm (drilled holes/pads/POWER isolation area) through hole vias; for some high-density high speed board design, 0.20mm/0.46 can also be used. For pcb via hole of mm/0.86mm, you can also try non-through vias; for power or ground circuit board via, you can consider using a larger size to reduce impedance;

(2) The larger the POWER isolation area, the better, considering the through hole vias density on the PCB, generally D1=D2+0.41;

(3) The signal traces on the PCB should not be changed as much as possible. In other words, we should minimize the changes in vias in pcb design.

(4) The use of a thinner PCB is conducive to reducing the two parasitic parameters of the circuit board via;

(5) The power and ground pins should be close to the through hole vias. The shorter the lead between the vias and the pins, the better the inductance will increase. At the same time, the power and ground leads should be as thick as possible to reduce impedance;

(6) Place some grounding vias near the vias of the signal layer to provide a short-distance loop for the signal.

In addition, the length of vias in pcb design is also the main factor affecting the via inductance. For the pcb via holes used for the top and bottom layers, the via length is equal to the PCB thickness. Due to the continuous increase in layers of a pcb, the PCB thickness often reaches more than 5 mm.

However, in high speed online pcb design, in order to reduce the problems caused by vias, the length of pcb via hole is generally controlled within 2.0mm. For pcb via hole with a length greater than 2.0 mm, the continuity of via impedance can be improved to a certain extent by increasing the aperture of the via. When the pcb via hole length is 1.0 mm or less, the best via hole diameter is 0.20 mm ~ 0.30 mm.