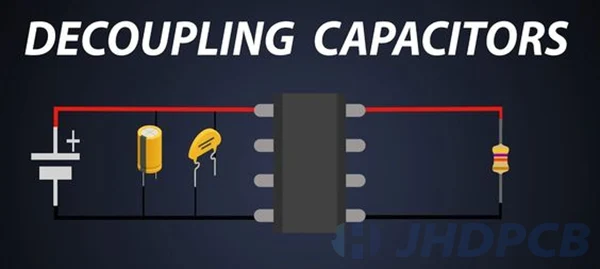

Decoupling capacitors are an integral part of any PCB design as they help to mitigate noise and stabilize voltage levels. These capacitors are strategically placed near integrated circuits (ICs) to provide a low-impedance path for high-frequency noise generated by the ICs. By reducing noise, decoupling capacitors enhance the overall performance and reliability of electronic devices.

Similarly, bypass capacitors also contribute to the optimal functioning of PCBs by minimizing noise and maintaining voltage stability. These capacitors serve as local energy reservoirs, storing and releasing energy when needed, thereby maintaining a steady supply of power to sensitive components. By eliminating voltage fluctuations, bypass capacitors enhance the signal integrity and reduce the risk of malfunctions or damage to the circuitry.

What Is A Decoupling Capacitor?

A decoupling capacitor, also referred to as a bypass capacitor or power filter capacitor, is an electronic device used to mitigate or eliminate noise and voltage variations in electronic circuits.

In electrical circuits, elements are energized by a source of electricity or voltage stabilizer. However, the circuit’s intrinsic characteristics and the presence of other components can cause deviations in the supplied voltage, resulting in circuit noise and interference that can lead to reduced performance or malfunction.

A decouple capacitor is positioned in parallel with the power source or voltage regulator, serving as a low-impedance channel for high-frequency noise and voltage deviations. In the case of a voltage regulator, a voltage regulator decoupling capacitor is placed in parallel with the regulator to ensure that the output voltage is free from fluctuations caused by high-frequency noise.It functions as a shield that absorbs any voltage surges or drops, ensuring a stable voltage supply to the components while minimizing electromagnetic interference (EMI) and radio frequency interference (RFI) in the circuit.

Decoupling capacitors are often employed in digital circuits, microprocessors, and other high-speed electronics. They come in various types and values, with the specific choice based on the circuit requirements. Ceramic, tantalum, and aluminum electrolytic capacitors are among the most common decoupling capacitor types.

In summary, decoupling capacitors are critical electronic circuit devices, ensuring stability and reliability by mitigating noise and voltage fluctuations.

What Does A Decoupling Capacitor Do?

As the core material of PCB, the three main raw materials for the production of CCL include glass fiber cloth, epoxy resin and copper foil, and PCB relies on them to realize the functions of conduction, insulation and support. Among them, glass fiber cloth and epoxy resin are often used as prepregs.

Offer DC Power to Active Components

Mitigate Voltage Fluctuations

Enhance Signal Integrity

Prevent Interference

How To Use Decoupling Capacitors?

Decoupling capacitors are employed in electronic circuits to minimize noise and fluctuations in voltage. They are ordinarily situated between the power source and ground and contribute to steadying the voltage at the IC or component that is being powered. Below are some guidelines for utilizing decoupling capacitors:

- Choose the appropriate capacitor type: Decoupling capacitors should have high capacitance values and low ESR (Equivalent Series Resistance). Ceramic capacitors are a popular choice for decoupling since they have low ESR and are available in high capacitance values.

- Position the capacitor in close vicinity to the IC: The capacitor for decoupling must be positioned in immediate proximity to the IC or component receiving power. This minimizes the length of the power traces, which can act as antennas and pick up noise.

- Use multiple capacitors: Using multiple decoupling capacitors of varying values can help to filter out a wider range of frequencies. For instance, you could use a 0.1uF ceramic capacitor in conjunction with a 10uF tantalum capacitor.

- Implement a ground plane: A ground plane can provide a low-impedance ground connection for the decoupling capacitor. This is particularly crucial for high-frequency circuits.

By following these guidelines, one can effectively utilize decoupling capacitors to reduce noise, improve power supply stability, and enhance the overall performance of electronic circuits.

What Is A Bypass Capacitor?

Bypass capacitors are essential constituents of electronic circuits, and they perform a critical function in filtering out AC noise from DC signals. They achieve this by connecting between the VCC and GND points of integrated circuits, forming an expedient path to ground that circumvents noise. Capacitors serve as highly effective filters that remove noise caused by various devices and components present within the system.

In operation, bypass capacitors provide a pathway of minimal resistance for AC signals to ground, enabling the delivery of pure DC signals. For example, in a transistor circuit, the bypass capacitor eliminates AC ripple effects from the DC voltage to guarantee that the transistor receives pure DC signals to amplify. Many DC power sources, such as power supplies, often emit unwanted AC noise and current surges that can introduce undesirable interference into electronic circuits. By using a bypass capacitor, circuit designers eliminate the noise, ensuring that only clean DC signals are delivered to active components.

Furthermore, bypass capacitors offer high impedance to low-frequency signals like DC signals, but their impedance is much lower towards high-frequency signals like AC signals. This functionality enables AC noise to travel through the capacitor and reach the ground while transmitting the DC signal through the resistor. Designers incorporate bypass capacitors within electronic circuits to guarantee that the circuits operate solely on clean and noise-free DC signals.

In brief, bypass capacitors are crucial components in contemporary electronics because they filter out unwanted noise from DC signals. They function by directing AC noise to the ground while enabling clean DC signals to pass through. Designers of electronic circuits must exercise caution when selecting bypass capacitors to ensure optimal performance and minimal noise.

What Is The Difference Between A Bypass Capacitor And A Decoupling Capacitor?

Decoupling capacitors and bypass capacitors can serve as anti-interference components in electronic circuits, but they are positioned differently. In the same circuit, the bypass capacitor removes high-frequency noise carried by the previous stage circuit from the input signal. On the other hand, the decoupling capacitor eliminates interference from the output signal and prevents the interference signal from being reflected back to the power supply. This is the fundamental distinction between them.

The decoupling capacitor stores energy and releases it back into the power supply to maintain a steady current flow. The bypass capacitor offers a path for the AC signal to return to switch between the power and ground rails. Both bypass and decoupling capacitors are interchangeable because of their shared purpose and function. The primary objective when energizing any device is to establish a low-impedance pathway in relation to the input power ground. However, there are a few noticeable differences:

- Bypass capacitors are utilized to provide a low impedance path for high-frequency noise signals. They ensure that high-frequency noise is suppressed before it spreads throughout the entire circuit, which could cause circuit malfunction and EMI issues. Conversely, decoupling capacitors are utilized to stabilize voltage variations.

- For low impedance bypassing, a solitary electrolytic capacitor would suffice, but for signal stabilization, the utilization of two dissimilar capacitor types is imperative.

How To Choose A Decoupling Capacitor?

Select the value of the decoupling capacitor:

Choosing the Size of a Decoupling Capacitor:

Decoupling capacitor calculation:

How To Choose The Value Of The Bypass Capacitor?

When adding a capacitor to a circuit, the reactance of the capacitor must be no more than 1/10th of the parallel resistance. As current prefers to travel through the path with the least resistance, a capacitor with a lower resistance is necessary to shunt the AC signal to the ground. To determine the capacitance value for the bypass capacitor needed, utilize the following formula:

C = 1/2πfXC

Suppose you must determine the capacitance of a capacitor connected to a resistor with a resistance of 440Ω. We know that the reactance must always equal 1/10th of the resistance, implying a reactance value of 44Ω. Also, it should be noted that the normal operating frequency of the electrical power grid in India is 50 hertz. Therefore, you may calculate the bypass capacitor’s capacitance using the formula below:

C = 1/2(3.14)(50)(44)

Based on the formula provided earlier, the calculated capacitance of the capacitor connected to the 440 Ω resistor is 73µF. This capacitance value can be used as a reference to determine the appropriate capacitor(s) to use in a circuit.

Where To Place Decoupling Capacitors?

To achieve efficient decoupling capacitor placement, decoupling capacitor layout should follow the following guidelines:

- It is advisable to position the capacitor in immediate proximity to the source signal it is intended to decouple.For ICs, this entails positioning the capacitor at the pin, while for input and output signals, it should be located near the connector.

- To eliminate low-frequency transients from input and output signal paths, it is recommended to connect the capacitor in-line with the trace. By doing so, the capacitor permits high-frequency signals to pass while blocking low-frequency and DC signals. The use of small capacitors is recommended for high-frequency transients, while large capacitors are suitable for low-frequency transients.

- When dealing with power pins and grounds, the goal is to eliminate AC or couple DC for power distribution and grounding. Hence, it is advisable to connect the capacitor in parallel with the signal path.

- In addition, decoupling capacitors can be connected in parallel with resistors to filter out undesired high-frequency signals while permitting low-frequency and DC signals to pass.

- To guarantee that current passes through the plane when utilizing vias to reach the power plane, it is suggested to first connect the capacitor to the component pin, and then to the via.

- Isolating analog and digital returns is feasible with decoupling capacitors. One way to achieve this is by linking a capacitor between the AC and digital ground pours on the same layer of the PCB.

In addition to proper placement, effective decoupling for power supplies on multisignal boards also requires the application of sound grounding practices. In the case of ICs with BGAs, it might be necessary to use dogbone routing and vias in order to integrate decoupling capacitors. Nevertheless, if the power and ground connections are located adjacently on internal balls, it is feasible to establish a direct connection to the power and ground planes by the use of microvias.

What Types Of Capacitors Are Used For Decoupling?

Functional Classification:

Decoupling capacitors are essential components of electronic circuits that aid in stabilizing the power supply voltage. They can be classified into three types: global, local, and inter-board decoupling capacitors.

- Global decoupling capacitors operate in the low-frequency range and provide a single current source for the entire circuit board to compensate for the noise generated during operation. Their capacitance is usually 50 to 100 times the sum of all load capacitances on the PCB. It is recommended to place them near high-density printed lines of power and ground wires on the PCB to ensure low-frequency decoupling without affecting the placement of critical printed lines.

- Local decoupling capacitors serve two functions: stabilizing the power supply voltage obtained by the integrated chip and providing an adjacent high-frequency channel for the transient current of the integrated chip. This reduces radiation noise while suppressing impedance coupling. The local decoupling capacitor is positioned as close as possible to the chip between the power supply terminal and the ground terminal of each integrated chip.

- Inter-board decoupling capacitors are located between the power plane and ground plane and represent the primary source of decoupling current at high frequencies. Capacitance between the planes can be increased by enlarging the area between the power layer and the ground layer. Replacing some ground planes with power isolation areas can also help increase the capacitance between the planes.

- Capacitors utilized for high-frequency decoupling: These capacitors serve to eliminate high-frequency interference that may disrupt the functioning of delicate electronic components. They usually have a low capacitance value and are relatively small in size.

- Capacitors employed for low-frequency decoupling: These capacitors are designed to eradicate low-frequency noise that can result in power supply instability. They typically possess a higher capacitance value and are generally larger in physical dimensions.

Material Classification:

In terms of materials, there exist numerous types of capacitors that are utilized for decoupling purposes:

- Ceramic capacitors: These capacitors are frequently utilized for high-frequency decoupling as a result of their low inductance and high stability. They can be obtained in a diverse range of capacitance values and can be either surface-mounted or through-hole. Apart from their application in high-frequency decoupling, ceramic capacitors are frequently utilized for signal coupling and filtering in electronic circuits. They possess a low dissipation factor, which renders them beneficial for circuits requiring minimal energy loss. Additionally, ceramic capacitors exhibit high tolerance to operating temperatures, which makes them appropriate for deployment in high-temperature settings.

- Tantalum capacitors: These capacitors find common use in low-frequency decoupling applications due to their high capacitance value and low ESR (Equivalent Series Resistance). They come in both surface-mounted and through-hole packages.Tantalum capacitors are classified as polarized capacitors, implying that they must be appropriately connected to a circuit with the correct polarity. They possess high capacitance density and exceptional volumetric efficiency, making them a fitting option for deployment in small electronic devices like laptops and smartphones. Nevertheless, tantalum capacitors are vulnerable to voltage spikes and may suffer damage if exposed to excessive voltage or current.

- Aluminum electrolytic capacitors: These capacitors see common usage in low-frequency decoupling applications because of their low cost and high capacitance values. They are typically polarized and available only in through-hole packages. Aluminum electrolytic capacitors feature a moderately elevated ESR (Equivalent Series Resistance) in contrast to other categories of capacitors, which renders them less than ideal for high-frequency applications. They also possess a finite lifespan and are prone to deterioration over time, which may adversely impact their functionality within the circuit. Nevertheless, aluminum electrolytic capacitors are reasonably priced and widely accessible, which contributes to their popularity as a preferred option for low-frequency decoupling tasks.

- Film capacitors: These capacitors are employed for both high and low-frequency decoupling requirements and come in a wide range of capacitance values and voltage ratings. Normally, they are more expensive than ceramic or electrolytic capacitors and are offered in both surface mount and through-hole types of packages.Film capacitors can be produced utilizing diverse materials, like polyester, polypropylene, and polycarbonate. They boast remarkable insulation resistance and stability across an extensive gamut of temperatures and frequencies. Film capacitors are employed in circuits necessitating high precision and negligible losses, for instance, audio equipment and power supplies. High-voltage film capacitors are also accessible, and they can endure high operating temperatures, rendering them fitting for deployment in stringent environments.

What Factors Affect PCB Decoupling Capacitors?

Decoupling capacitors on a PCB are indispensable for minimizing noise and ensuring that integrated circuits on the board receive stable voltage levels. When designing a PCB, it is necessary to take various factors influencing decoupling capacitors into account.

- Capacitance Value: The capacitance rating of a decoupling capacitor is essential as it determines the amount of energy that the capacitor can store or release. It is crucial to choose the appropriate capacitance rating that matches the circuit’s requirements. A capacitor with an insufficient capacitance rating may not provide adequate filtering, while one with an excessive capacitance rating may result in unfavorable impacts due to longer charging/discharging times and increased circuit time constants.

- Frequency Response: The decoupling capacitor frequency characteristic is critical because it affects the capacitor’s ability to filter out noise. Ceramic capacitors exhibit lower impedance across a broad frequency range and are beneficial for filtering high-frequency noise. Tantalum and electrolytic capacitors have a narrower frequency range, making them more suitable for lower frequency noise.

- ESR (Equivalent Series Resistance):ESR is a significant consideration when selecting the capacitor type for decoupling. Tantalum capacitors have low ESR, making them suitable for analog circuits. In contrast, ceramic capacitors have higher ESR, making them more effective for high-frequency digital circuits.

- Temperature Rating: The temperature rating of a decoupling capacitor is also a crucial factor to consider when choosing the capacitor. The operating temperature range of the PCB must fall within the capacitor’s specification to ensure dependable performance and prevent failure.

- Dimensions: The physical dimensions of a capacitor are another consideration when designing a PCB layout. Capacitors come in different sizes, and selecting the appropriate size will depend on the amount of space available and the required capacitance level.

- Voltage Rating: The voltage rating of a decoupling capacitor can impact its performance in several ways, such as selecting an appropriate voltage rating to prevent breakdown, taking into account capacitance variation and increased leakage current at higher voltages, and also considering possible dielectric breakdown at extremely high voltages.